The flow-through scale guarantees precise control of the weight of the produced pellets after their cooling and sorting.

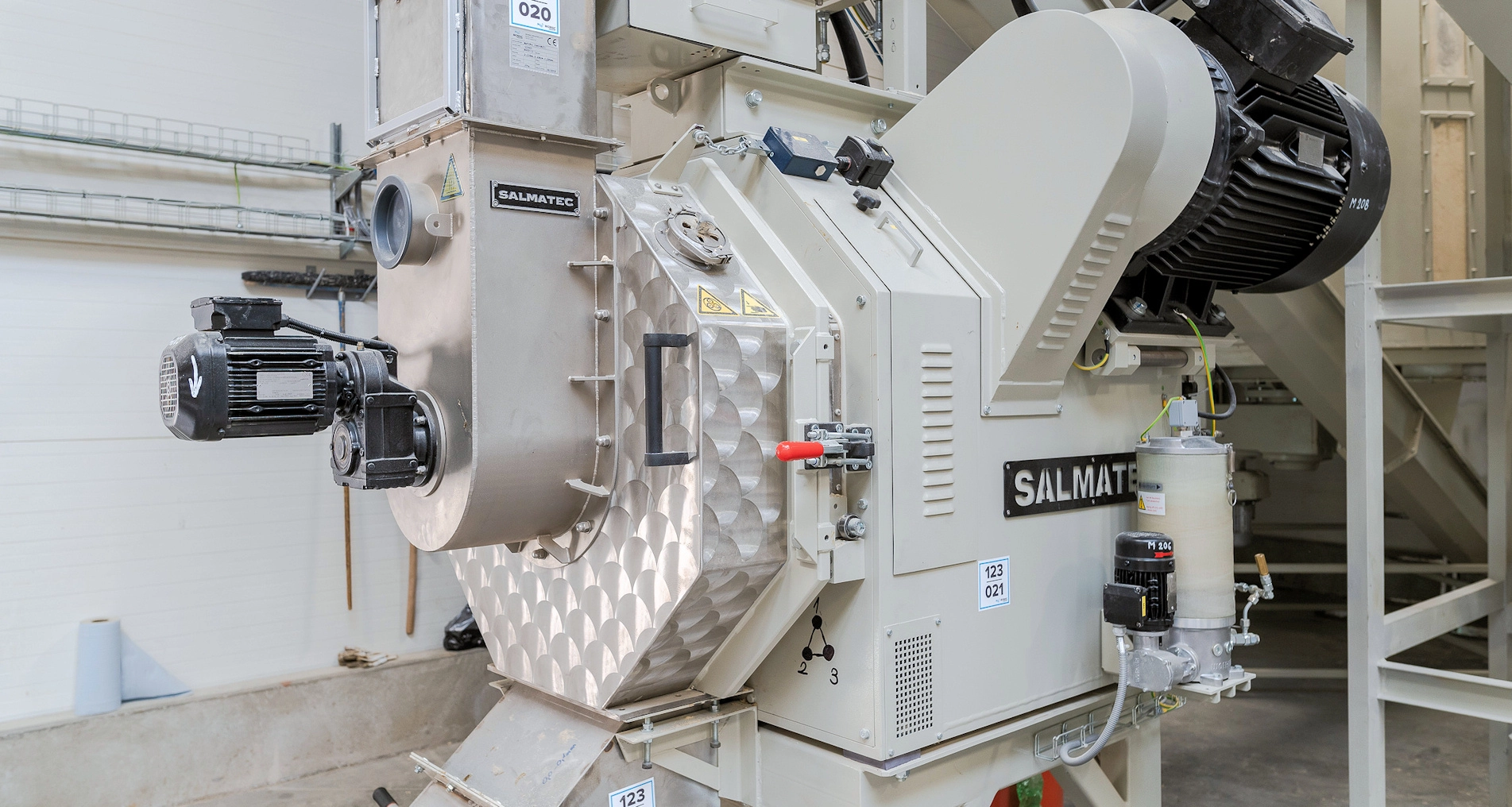

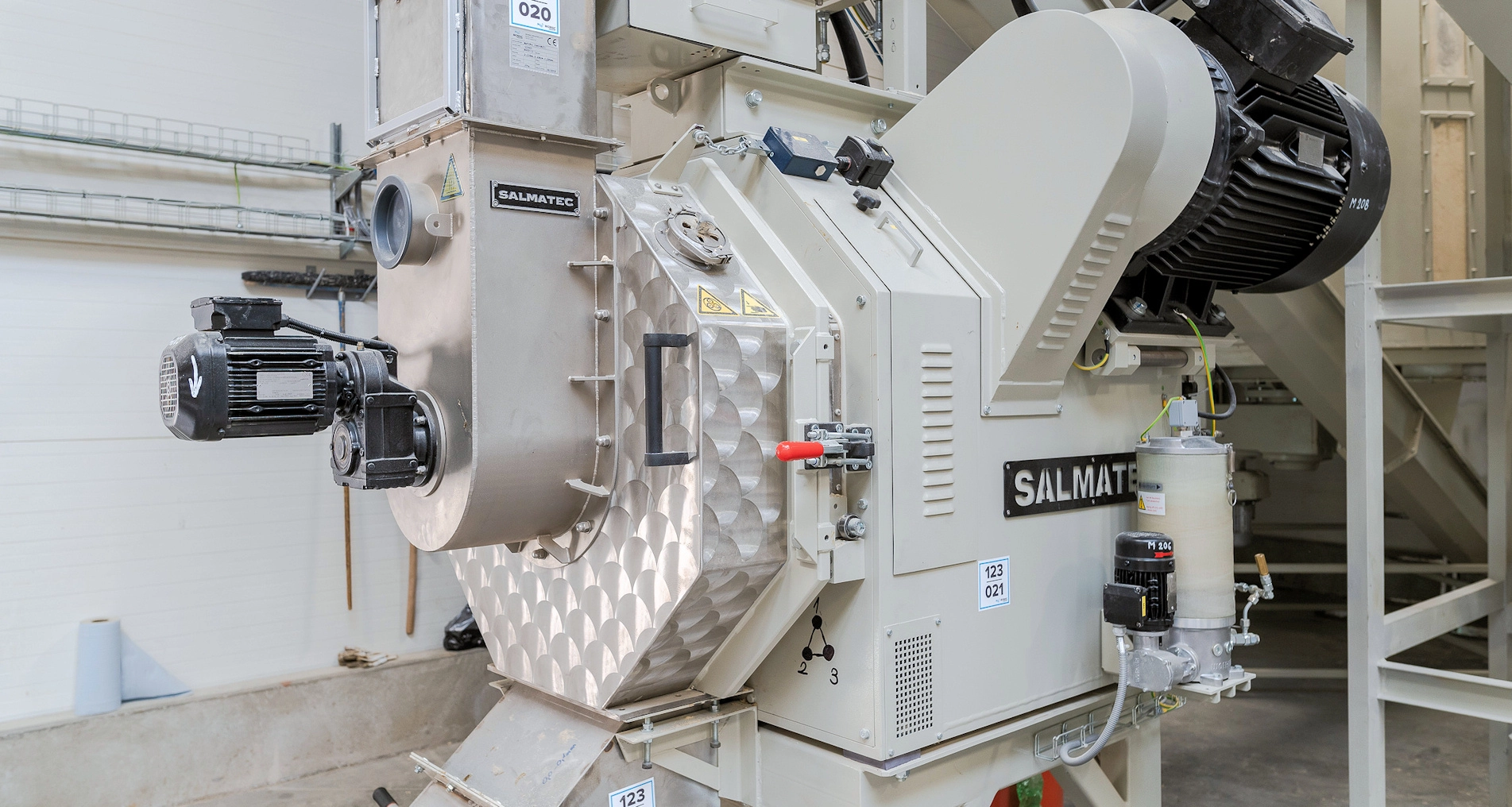

The modular design of pellet presses can be perfectly adapted to various customer requirements.

A wipe tester is a device for determining the mechanical resistance of pellets. Documenting the mechanical resistance of pellets is an important part of producing pellets of the highest quality.

A vibrating screener is a device for the removal of dust from pellets that is generated when the pellets pass through the conveying paths or the pressing die.

Robotic placement of pellet bags on a pallet guarantees higher productivity, reliability and a precise final pallet shape.